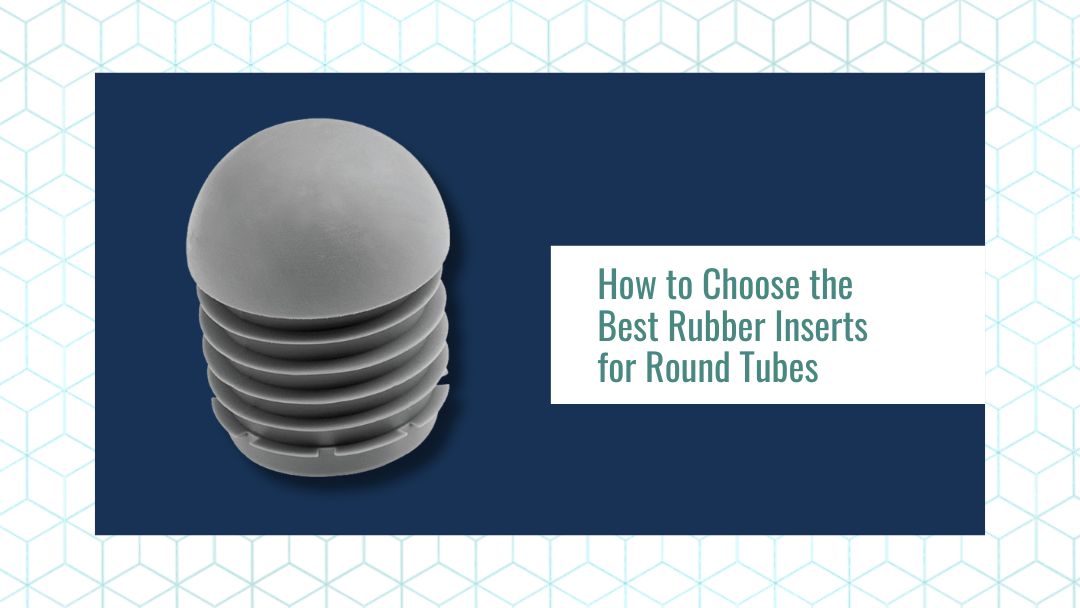

Ribbed for multiple uses

Rubber inserts for round tubes play a crucial role as end pieces in countless tubular structures. Given their importance, choosing the right round rubber insert is essential to ensure the durability and safety of the structure. Different usage conditions or environments will require inserts with specific features.

Below, we’ll explore the types available and how to choose the most suitable option for each need.

Types of Rubber Inserts for Round Tubes

Fortaps, as a specialized manufacturer of end caps, offers a wide range of round tube inserts to cover all needs. Below is a summary of the main types of rubber inserts for round tubes available:

- Standard Ribbed Internal Inserts: These are inserted into the tube and have fins for a firm fit. They are the most common in chair legs, tables, and railings. They provide internal protection against dirt and moisture, as well as a clean and safe finish.

- Reinforced Internal Inserts: Made from more robust materials, these are ideal for structures subject to heavy loads or impacts, such as machinery or metal frames. They do not deform easily and offer greater durability in demanding environments.

- Inserts with Special Heads (Flat or Hemispherical)

-

-

Flat: Fit flush with the tube, offering a discreet and elegant design.

-

Hemispherical: Provide better grip and cushioning, especially useful in chair legs, walkers, or canes. Fortaps offers anti-slip models ideal for delicate floors.

- Threaded Internal Inserts: Feature a metal thread that allows leveling feet or wheels to be screwed in. Common in industrial furniture and structures requiring height adjustment.

- Decorative Internal Inserts: Designed to add aesthetic value, with chrome or glossy finishes. Ideal for designer furniture where final appearance is important without sacrificing protective function.

- External Round Inserts: Placed over the outer edge of the tube (rather than inside) and are useful when an internal insert is not feasible. Fortaps offers reinforced options, especially suited for railings or large-diameter posts.

- Inserts for Canes and Supports: Designed for direct contact with the ground, made of semi-soft rubber and some models include a metal washer for added resistance. Perfect for orthopedic devices, walkers, or umbrellas.

- Flexible External Inserts: Made of elastic rubber, they easily adapt to the contour of the tube, even with slight size variations. Their flexibility helps absorb impacts and makes installation easier.

Recommendations for Choosing the Most Suitable Round Rubber Insert

Not all inserts are the same, and choosing the right one will depend on the specific needs of your project. We recommend evaluating the following key aspects before deciding which round rubber insert to use:

-

Tube Dimensions: Make sure the tube’s diameter and wall thickness match the insert’s range for a secure and tight fit.

-

Environment of Use: Consider whether the insert will be used indoors, outdoors, or in harsh environments to choose the most resistant material.

-

Type of Application: Depending on the use (furniture, machinery, signage…), prioritize resistance, stability, protection, or finish.

-

Aesthetics and Customization: Consider whether you need a specific color, visible finish, or to include a logo to reinforce your product’s image.

-

Technical Support: If you’re unsure, consult the Fortaps team to choose the most suitable option for your needs.

Why Choose Fortaps’ Round Rubber Inserts for Tubes?

Fortaps’ round rubber inserts stand out thanks to their optimized technical design and the backing of a specialized manufacturer. These are the key factors that make them a reliable and versatile solution:

-

Easy Installation: Press-fit without tools, with fins that ensure a firm and stable hold even under vibration.

-

Total Adaptability: The internal fins allow the insert to adjust to different tube diameters and wall thicknesses, covering wide ranges with a single reference.

-

High Resistance: Made from high-quality virgin polyethylene, they withstand impacts, intensive use, extreme temperatures, and harsh environments without deforming.

-

Professional Finish: Available in various colors, smooth or non-slip surfaces, and even with the option to include logos or chrome finishes.

-

Stock and Speed: Fortaps maintains permanent stock of the most in-demand models and offers 24/48h delivery to avoid delays in production or assembly.

-

Extensive and Customizable Catalog: A wide variety of shapes and sizes in stock, with the option to develop custom solutions for special projects.

-

Expert Technical Support: An online assistant and personalized service to help you select the ideal insert for your application.

With Fortaps, you get durable, functional inserts ready to integrate into any setting—with the peace of mind that comes from working with an expert supplier who supports you throughout every phase of your project.

Ribbed for multiple uses

If you need tube inserts for metal tubes and want the best protection, choosing the right insert is essential. However, we understand that with so many types, sizes, and materials available, the process can seem complex. That’s why we’ve created this guide to help you make the best decision easily and effectively.

The Importance of Tube Inserts

Although in many cases their selection might appear to be purely aesthetic, tube inserts are key components that seal the ends and help preserve the integrity of the pieces. Their function is twofold: to protect the user and to extend the lifespan of the tube. They prevent the entry of dirt, moisture, or debris, stop internal wear due to rust or corrosion, and eliminate sharp edges that could pose a risk of injury.

To know which one is the most suitable, it’s important to understand the different types available and what sets them apart.

Types of Tube Inserts

Tube Inserts by Shape

-

Round inserts: For cylindrical ends, commonly used in railings, handrails, or chair legs with a circular cross-section.

-

Square inserts: Designed for square-profile sections, they provide a flat finish flush with the tube, ideal for furniture and standard structures.

-

Rectangular inserts: Suitable for rectangular-section tubes, they ensure a full seal along both axes of the profile and prevent exposed corners.

-

Oval inserts: Used in design elements or specific equipment, they fit profiles with more organic or aerodynamic shapes.

Tube Inserts by Mounting Type

-

Internal inserts: Inserted inside the tube, with fins that ensure a snug fit without protruding from the edge. They maintain the outer dimensions of the structure intact.

-

External inserts: Cover the end of the tube from the outside like an enclosing cap. Useful when an internal insert can’t be used or when extra edge protection is needed.

-

Custom inserts: Manufactured for profiles with non-standard dimensions or shapes, or with specific requirements such as logos, colors, or reinforced materials.

Tube Inserts by Material

-

Low-Density Polyethylene (LDPE): Affordable and flexible, ideal for standard applications due to its ease of insertion and good general resistance.

-

High-Density Polyethylene (HDPE): More rigid and durable, recommended for demanding or heavy-duty environments.

-

ABS: A technical plastic with high impact resistance and excellent finish, suitable for machinery or structures that require robustness and aesthetics.

-

Thermoplastic Rubber (TPE): Combines elasticity and grip, ideal for irregular surfaces or when a non-slip effect is needed, such as the bases of equipment or machine legs.

Most Common Applications of Tube Inserts for Metal Tubes

Tube inserts are widely used across many industries, offering protection, safety, and a clean finish. Some of their most frequent applications include:

-

Furniture manufacturers: Prevent noise, scratches, and slipping in chairs, tables, or cabinets; they also withstand heavy use in communal areas.

-

Metal structures: Seal tubes to prevent the ingress of water or dust and protect users by covering sharp edges.

-

Urban furniture and signage: Provide both aesthetics and protection against weather in benches, bins, poles, or streetlights.

-

Fencing and scaffolding: Eliminate sharp corners, prevent accidents, and avoid internal corrosion of the tube.

-

Industrial and agricultural vehicles: Protect tubes from moisture, mud, and vibrations, prolonging the frame’s lifespan.

-

Industrial distributors: Offer versatile, in-stock solutions to supply sectors such as construction, metalworking, or furniture manufacturing.

How to Choose the Right Tube Insert for Metal Tubes

To select the ideal insert, it’s essential to consider key aspects that ensure the product performs effectively:

-

Shape and size: The insert must match the shape of the tube (round, square, etc.) and fit its internal or external dimensions.

-

Usage environment: Consider whether it will be exposed to moisture, weather, chemicals, or extreme temperatures.

-

Material: Choose the appropriate material based on the required function (protection, anti-slip, impact resistance, etc.).

-

Size compatibility: Ensure the tube’s diameter and wall thickness match the insert’s specifications.

-

Trusted supplier: Opt for a manufacturer that offers technical advice, certified quality, and immediate availability.

Fortaps: The Supplier You Need for High-Quality Metal Tube Inserts

At Fortaps, we provide a technical, comprehensive solution tailored to each client’s requirements. Here are some of our standout advantages:

-

Virgin material manufacturing: We use only virgin plastic to ensure superior strength, durability, and uniformity.

-

Custom inserts: We develop special solutions for non-standard profiles or specific needs in terms of strength, color, or customization.

-

Extensive catalog in stock: A wide variety of sizes, shapes, and materials to cover all market applications.

-

Fast delivery: We ship within 48 to 72 hours, enabling quick responses for urgent projects.

-

Virtual assistant on our website: Step-by-step guidance to help you identify the most suitable insert based on the tube type, dimensions, and usage conditions.

Ribbed for multiple uses

Custom end caps for trailers, installed on metal profiles or structural points, play a fundamental role in the durability and functionality of trailers—whether industrial, agricultural, or for specialized transport.

In this article, we’ll show you how to choose the end caps that best suit your needs.

The Importance of Custom End Caps for Trailers

Custom end caps offer more than just an aesthetic touch; they provide essential protection against factors like moisture and corrosion.This is particularly important in agricultural and industrial settings, where trailers are constantly exposed to harsh weather conditions.

The main protective functions of custom end caps include:

-

Blocking dirt, rust, and moisture

-

Preventing debris from entering pipes and structural elements

-

Absorbing impact and friction

Features of Custom End Caps for Trailers

In addition to the benefits of standard caps, custom end caps provide added advantages that make a real difference:

-

Perfect fit for stable attachment, enhancing safety and prolonging the trailer’s lifespan

-

Customization options depending on the application—for example, anti-slip textures for trailers operating on slopes or uneven terrain

-

Use of specific materials based on the trailer type and the environmental or mechanical conditions

-

More aesthetic finish thanks to custom design

How to Choose Custom End Caps for Trailers

While it’s always best to consult a trusted manufacturer, here are key aspects to consider when making your choice:

-

Exact measurements of the tube where the end cap will be installed: outer diameter, wall thickness, and tube shape

-

Usage conditions, which determine the most suitable material. We recommend materials like polyethylene or polyamide for their high resistance to wear, impact, mechanical stress, extreme temperatures, and chemicals—especially useful for agricultural and industrial trailers

Helping You Find the Right End Cap for Your Trailer

At FORTAPS, we are a leading manufacturer of end caps, finishing caps, leveling feet, and other technical components. We design custom end caps for trailers tailored to your specific usage, including aesthetic options such as color, logo, or product name engraved on the cap. To help you find the ideal trailer end cap, we offer two support channels:

-

Direct contact: Call us, schedule a meeting, or fill out our contact form

-

Smart assistant on our website: Simply enter your required measurements and get a personalized product recommendation

We’ve manufactured custom trailer end caps for a wide range of industries—industrial, agricultural, transport platforms, and even personal-use trailers. Our clients consistently highlight that our end caps:

At FORTAPS, we’re confident you’ll find the perfect solution in custom trailer end caps.

Ribbed for multiple uses

When ordering inserts for chair legs, many of our customers have expressed various doubts. To clarify them, in this article, as experts in ferrules, inserts, and leveling feet, we will explore the importance of using inserts for chair legs —just as we did with chair ferrules—, how to choose the most suitable ones, and the available solutions. Let’s get started!

The Importance of Inserts for Chair Legs

Using inserts for chair legs is essential as it offers multiple benefits and practical solutions. These inserts protect both the floor and the chair itself. For example, by installing them, you prevent wear and scratches on the floor, whether it is made of wood, tiles, or any other material.

It is important to highlight that, for instance, inserts for table legs differ from those for chairs, so these particularities must be considered to make an appropriate choice. Consult your supplier for guidance.

Main Benefits of Inserts for Chair Legs

Inserts for chair legs are essential elements that combine functionality, protection, and aesthetics, offering a wide range of advantages:

- Provide stability. Inserts for chair legs ensure better support for chairs, preventing unwanted movement and guaranteeing safer and more comfortable use for users.

- Reduce noise when moving chairs. Their design cushions the impact against the floor, minimizing the annoying sounds produced when moving furniture.

- Protect surfaces from wear and scratches. They act as a barrier between the chair legs and the floor, preventing damage to delicate materials such as wood, tiles, or carpets.

In addition to these benefits, inserts serve other important functions:

- Block the entry of dirt and moisture. Thanks to their perfect fit, they prevent particles or liquids from penetrating the inside of the legs, whether made of wood, metal, or other materials.

- Enhance the aesthetics of the furniture. Their clean and ergonomic finish contributes to making chairs look more attractive in any setting.

- Extend the durability of chairs. By preventing the accumulation of dirt, corrosion, and premature wear, they ensure a longer lifespan for both the legs and the protected surfaces.

What Do You Need to Know to Choose the Right Insert for Your Chair Legs?

When choosing the right inserts for your chairs, it is crucial to consider several aspects:

- Leg material: It is essential to consider the material of the legs, as some inserts, for example, are specifically designed for metal chair legs, while others are more suitable for wooden chairs. It is also worth noting that although there are inserts for metal chairs designed to fit these structures perfectly, more versatile materials exist, as we will see later.

- Precise measurements: It is important to measure the diameter of the legs accurately to ensure that the inserts fit correctly and provide the necessary support.

- Material quality: Choose high-quality inserts that are durable and resistant to wear, ensuring optimal long-term performance.

- Type of floor: The type of floor where the chairs will be used also influences the choice. Some inserts are specifically designed to protect surfaces such as tiles, wood, or carpets. Again, there are versatile materials like polyethylene that are suitable for all surfaces.

By following these guidelines, you can select the most suitable inserts for your chairs, ensuring their stability, protection, and long-term durability.

The Importance of Materials in an Insert for a Chair Leg

The material used in inserts for chair legs is a key factor in their manufacturing and performance. At FORTAPS, for example, polyethylene is used—a thermoplastic known for its high resistance and versatility. This material offers several advantages:

- High wear resistance: Extends the lifespan of chair legs.

- Insulating properties: Does not conduct electricity or heat, providing safety in different environments.

- Easy to mold: Thanks to the injection system, it allows for precise and high-quality finishes.

- Versatility: Ideal for all contexts. You only need to know the insert’s measurements to make your purchase and ensure excellent results.

Custom Chair Leg Inserts: The Ideal Solution

Custom inserts are a perfect solution for those looking for products tailored to the specific needs of each customer. These pieces offer important advantages:

- Perfect fit: They are specifically designed for each case, adapting to the shape, size, and use of the legs.

- Improved aesthetics: Thanks to their design and smooth finishes, they provide a decorative touch that enhances the appearance of the chairs.

How Do We Manufacture Custom Inserts for Chair Legs at FORTAPS?

At FORTAPS, the production of customised inserts for chair legs is based on the development of exclusive molds. When we manufacture custom inserts, we design specific molds adapted to the dimensions and needs of each client.

These inserts can serve multiple functions, and their design varies depending on their intended use. For example, oval-shaped models are ideal for decorative purposes, adding an extra aesthetic touch to chairs. Meanwhile, inserts designed for outdoor environments serve a dual function: not only beautifying but also protecting against moisture, ensuring greater durability.

Each custom project follows an approach tailored to the client’s specific requirements. The molds and designs are carefully adjusted to offer a product that combines functionality, aesthetics, and precision.

Ribbed for multiple uses

At Fortaps, we specialise mainly in the manufacture of ferrule, end caps and adjustable feet. This includes a diversity of ferrule alternatives, which allows each customer, depending on their sector, to have access to a product that meets their needs and objectives. On this occasion, we will talk in particular about the resistance and durability of outdoor ferrule and the characteristics that they must meet in order to be placed in outdoor environments.

Functions of outdoor ferrule

Outdoor ferrule have a variety of uses. Nowadays, as a consequence of the benefits they offer, plastic ferrule are becoming more and more common in outdoor applications. As for their applications, they can be found on traffic signs as well as on fence posts. They can also be found on billboards, among other diverse alternatives.

Among their different uses, we can highlight that the main purpose of the ferrule we manufacture at Fortaps is to act as plugs to protect metal pipes from corrosion. In this way, they prevent excessive wear that could affect their useful life. At the same time, they prevent cuts, injuries or accidents that people may suffer from contact.

The characteristics that outdoor ferrule must meet

Understanding the above mentioned, there are certain characteristics that the ferrule must fulfil in order to be able to develop their role. These characteristics, which are fulfilled by the Fortaps’ ferrule, are the following:

Correct fit and support

The first thing that the ferrule must comply with for their placement in outdoor installations is to have a good adaptation and fastening to the tube or pole on which they are going to be placed. Otherwise, the ferrule may end up moving, coming off or breaking.

To provide an answer to this, Fortaps, thanks to our more than 25 years of experience in the design of injection moulds, allows us to manufacture ferrule that are conceived, down to the last detail, to be able to fulfil their function properly. This includes their attachment to pipes or poles.

One thing we at Fortaps do in this regard is to incorporate flexible fins and inner ribs. In this way, we make sure that the ferrule are perfectly fixed to the tube.

Resistant material

We have previously discussed that outdoor ferrule must be able to protect pipes and poles from corrosion generated by environmental agents. In this sense, the second characteristic that all good outdoor ferrule must meet is to be resistant to weathering, even in extreme climates.

To achieve this, Fortaps injects our ferrule only in high quality virgin materials, especially low density polyethylene (PELD). The physical, mechanical and thermal properties of this material are certified for outdoor use, even in areas with extreme climatic conditions. What you get, then, is a plastic that does not shrink or expand, while at the same time it does not crack, which could make it brittle.

Despite the above, for installations that are placed in areas with really extreme climates, at Fortaps we are able to manufacture ferrule by adding a photo-stabilizing anti-UV additive that is specially designed to prevent the photo degradation of the plastic. It is also important to highlight the sustainability of Fortaps polyethylene, which comes from two different and complementary points such as the work processes with minimal energy consumption machinery and the material.

Quality dye

Finally, when we talk about quality dye, in the case of ferrule placed outdoors, we are referring to a dye that does not weaken the physical structure of the plastic.

Dyes are used because the virgin polyethylene used in these installations is a naturally translucent material. Therefore, it must be dyed in order to increase the material’s resistance to light.

At Fortaps we use pigments in the form of polyethylene-based master batches. This type of pigment allows us to ensure mass dyeing.

The design of Fortaps’ ferrule

Now that we have seen the characteristics that outdoor ferrule must meet, we want to tell you how Fortaps ferrule are designed. They are the result of a three-phase process: design, manufacturing and material selection.

These phases can be found in the tube dimensions, whether they are used for aluminum, steel or galvanized tubes (80×40, 40, 40, 50 or 60 mm, among others), or in other less frequent options (150×50, 100×50, 130, 140 and 150 mm).

In view of the above, we can highlight that the ferrule that we manufacture at Fortaps are perfectly adapted to outdoor installations. They are capable of protecting pipes made of different materials, even in areas with extreme weather conditions. If you need outdoor ferrule, do not hesitate, contact us.

Ribbed for multiple uses

At Fortaps, we have an increasing number of customers in the photovoltaic sector who are demanding the manufacture of our ferrules. This is because we are a company with more than 25 years of experience in the technical plastic injection sector, having developed as an international company and with the aim of obtaining the highest quality and excellence in our products. Today we will talk about ferrules in photovoltaic plant structures.

In addition, we have extensive experience in the installation of solar panels, as it aligns with our commitment to the environment and our environmental management system.

Components of photovoltaic systems

In order to function properly, photovoltaic systems have components of high technological value. These range from the wiring system to inverters, photovoltaic modules, batteries and monitoring systems, among others.

However, the fact remains that the whole of this technological value rests on a metal structure which acts as a load-bearing structure. The elements of this metal structure must, for their part, meet and correspond to the same requirements.

Taking this into account, both manufacturers and installers of photovoltaic panels are currently undergoing a major development due to the trend towards sustainability. Therefore, they are offering larger and more numerous installations.

The most important of these are the “solar gardens“, which have metal tube supporting structures that need to withstand the elements: gusts of rain and wind, extreme temperatures that may occur in the area where they are installed, etc.

Installation of the solar panel supports

In order to function properly, solar panel mounts tend to be anchored to the ground using large metal tube structures, i.e. 100, 120, 140 and 200 mm. This is to avoid some common and detrimental effects such as galloping or fluttering.

Fluttering is the aeroelastic instability generated by the wind and is characterised by large amplitude oscillations in structures. This, in turn, ends up producing a movement that can end up causing problems. Thus, the structures and the supported photovoltaic panels can be affected and end up “flying”.

At Fortaps, with our experience, we are well aware of this effect and how detrimental it can be to structures and facilities in general. We know this because our facilities are located adjacent to an airport. This means that they are in areas that are not very sheltered from the wind, as there are no tall buildings around them. That is why the solar roof of our manufacturing plant has been designed according to a casuistry that consists of a photovoltaic self-consumption installation, such as the one we realised with Wingreen mounted with a customised type of structure.

Fortaps ferrules to protect metal tubes in photovoltaic plant structures

Understanding the above aspects, manufacturers and installers are increasingly looking for effective tools to protect metal tube ends from the negative effects of moisture and corrosion caused by climatic exposure.

Faced with the need for these companies to protect metal tubes and thus guarantee the safety of supporting structures, installers are increasingly relying on Fortaps and the ferrules that we manufacture in-house.

Why use ferrules to protect metal tubes and structures in photovoltaic plant structures?

In order to understand this better, it is necessary to refer to the purpose of the ferrules. They ultimately aim to reduce the execution time of the structures, as well as the costs involved. This, without losing sight of the strict compliance with safety requirements.

In addition, the ferrules that we manufacture at Fortaps are characterised by their reliability, being able to replace the metal plates and caps that are welded to the end of the tubes.

Finally, these ferrules are manufactured from certified virgin materials and are highly weather-resistant for use in open spaces. They are resistant to environmental corrosion and also to the negative effects of UV exposure. All this has an impact on the durability and service life of the overall installation.

Solutions for the photovoltaic sector by Fortaps

In view of the above-mentioned aspects, we at Fortaps respond to the demands of customers in the photovoltaic sector by developing ferrules for special metal profiles. Here we include specialised ferrules that can be branded with the logo and company colours of the individual customer, in order to achieve a structure that reflects the personality of the brand.

To achieve this, at Fortaps we constantly work in collaboration between our technical department and the technical department of each individual customer. On our website you can find all the information you need to know about how our ferrules work and the benefits they can bring you.